Safepath AS

|

Report No.

|

1792 |

|

Type of audit

|

External Audits |

|

Auditee/Customer

|

Safepath AS |

|

Date

|

2017/05/22 |

|

Findings

|

4 |

|

Status

|

Closed |

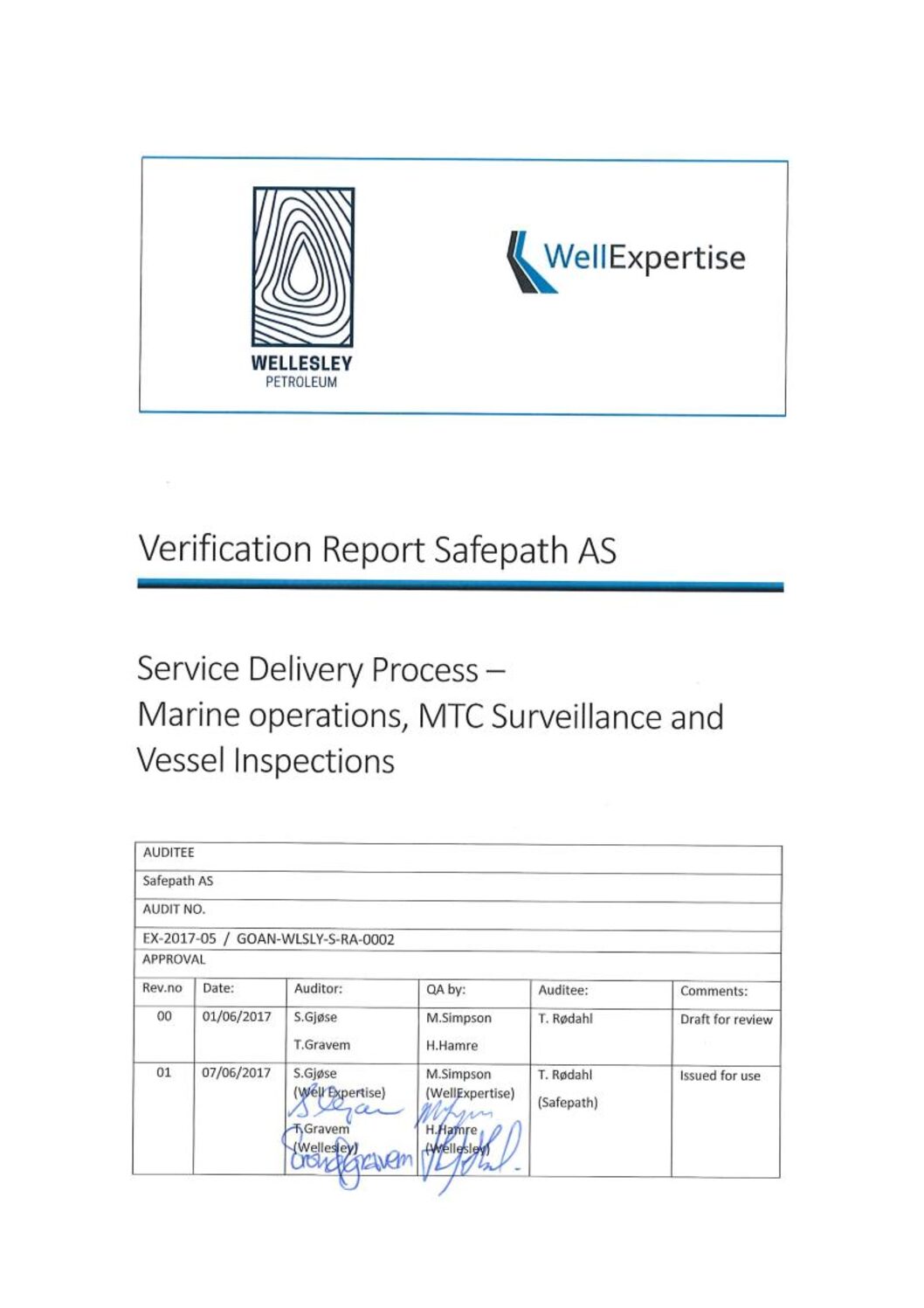

Verification Report Safepath AS

Summary

1. Ensure Safepath’s operational performance meets industry standards, Wellesley and Well Expertise

expectations. Assure internal Safepath processes behind HSE and operational performance are being

actively used as intended.

2. Ensure that Safepath have the capacity, resources and knowledge to provide Well Expertise and

Wellesley with the expected service levels and quality, given the current market conditions.

3. Verify Safepath have information required from Well Expertise and Wellesley to plan for 2017

operations.

4. Satisfy verification requirements for Wellesley and Well Expertise project execution

The audit was based on the following documents:

• GOMO: guidelines for marine operations

• Norsk Olje og Gass: Operations manual for offshore service vessels on NCS

• Well Expertise: Marine Operations

The following documentation was received from Safepath prior to the verification meeting:

• Safepath Marine Manual

• Styringssystem for Safepath AS

• Maritime Surveillance and Environmental Monitoring Service

• MTC Operasjonsmanual

Findings

-

Clarify scope of Safepath service delivery in planning

and operational phase. i.e. Emergency response

support; stateboard with area resource overview. OIM

support ship on collision course. Drills etc. Assess

benefit of introducing kick off meeting with customer as

part of planning. -

Clarify and define roles and responsibilities. Assess

need for requesting/documenting input/interfaces

required from operator as basis for planning

operations. -

Enterprise risk register; a risk register was not

requested/addressed in the meeting, however the verification team recommend that a collected overview

of risks associated with the company are identified and

documented in a company/enterprise risk register (if

not already in place.) -

Follow up of suppliers. Establish list over suppliers.

Define which have an influence on customer/project

delivery and assess criticality level. Follow up of

suppliers based on criticality level.

Additional Documentation

New Audit Report

\n

Safepath AS

|

Report No.

|

1792 |

|

Type of audit

|

External Audits |

|

Auditee/Customer

|

Safepath AS |

|

Date

|

2017/05/22 |

|

Findings

|

4 |

|

Status

|

Closed |

Verification Report Safepath AS

Summary

1. Ensure Safepath’s operational performance meets industry standards, Wellesley and Well Expertise

expectations. Assure internal Safepath processes behind HSE and operational performance are being

actively used as intended.

2. Ensure that Safepath have the capacity, resources and knowledge to provide Well Expertise and

Wellesley with the expected service levels and quality, given the current market conditions.

3. Verify Safepath have information required from Well Expertise and Wellesley to plan for 2017

operations.

4. Satisfy verification requirements for Wellesley and Well Expertise project execution

The audit was based on the following documents:

• GOMO: guidelines for marine operations

• Norsk Olje og Gass: Operations manual for offshore service vessels on NCS

• Well Expertise: Marine Operations

The following documentation was received from Safepath prior to the verification meeting:

• Safepath Marine Manual

• Styringssystem for Safepath AS

• Maritime Surveillance and Environmental Monitoring Service

• MTC Operasjonsmanual

Findings

-

Clarify scope of Safepath service delivery in planning

and operational phase. i.e. Emergency response

support; stateboard with area resource overview. OIM

support ship on collision course. Drills etc. Assess

benefit of introducing kick off meeting with customer as

part of planning. -

Clarify and define roles and responsibilities. Assess

need for requesting/documenting input/interfaces

required from operator as basis for planning

operations. -

Enterprise risk register; a risk register was not

requested/addressed in the meeting, however the verification team recommend that a collected overview

of risks associated with the company are identified and

documented in a company/enterprise risk register (if

not already in place.) -

Follow up of suppliers. Establish list over suppliers.

Define which have an influence on customer/project

delivery and assess criticality level. Follow up of

suppliers based on criticality level.

Additional Documentation